CONNECTICUT

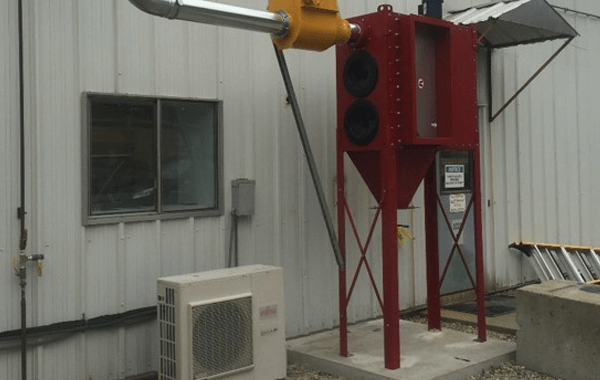

AQUEST CORPORATION provided an efficient, compact and cost-effective solution to control dust from a titanium shot-blasting operation at a Connecticut aerospace parts manufacturing facility. Aquest utilized the MicroAir RP2 cartridge style dust collector. The dust collector was equipped with an explosion backdraft damper (yellow device pictured), deflagration relief venting (silver panel pictured), and infrared spark detection / suppression system (inside, not pictured) in compliance with NFPA 484 and OSHA’s combustible dust collection and fire prevention requirements. The dust collector was designed to provide adequate suction to transport dust at sufficient velocity thereby mitigating a significant fire hazard.