CONNECTICUT

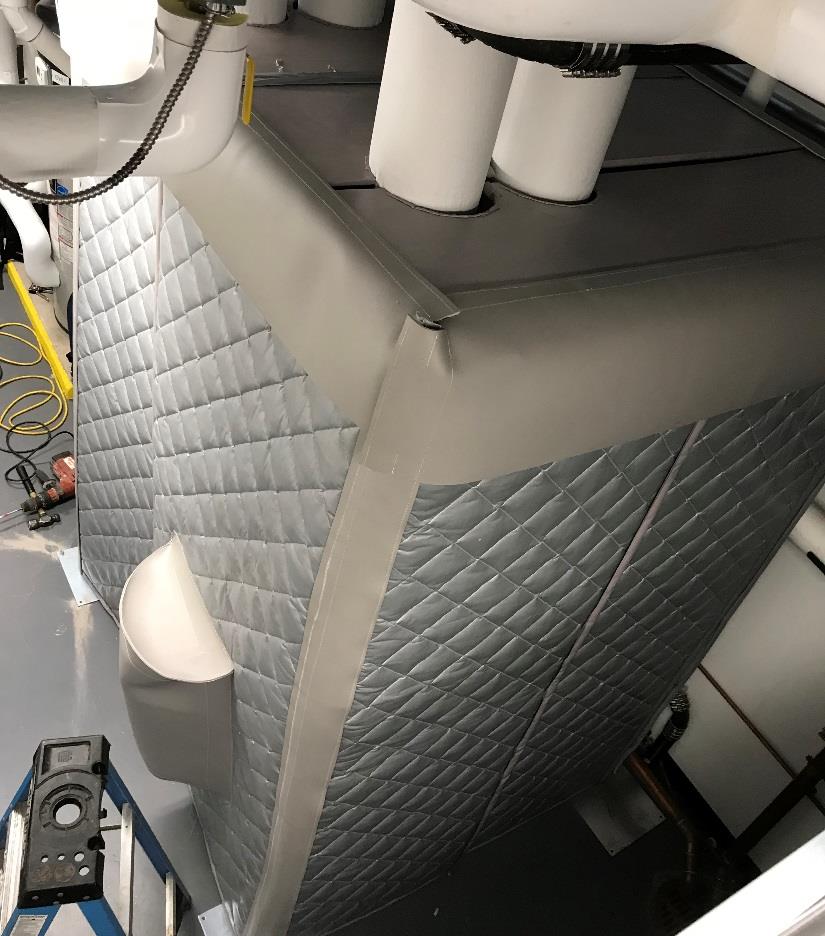

AQUEST CORPORATION constructed two custom acoustical machine enclosures in a confined mechanical room at a facility in CT. The machinery located in the room was causing disturbances in nearby offices. Each of the enclosures needed to be designed with numerous piping and conduit penetrations to fully surround the skid mounted equipment. The four-sided, closed-top enclosures were equipped with vent baffles to allow for heat dissipation, and the BSC-25 barrier-absorber composite panels were suspended from a double-track rail system to allow for the panels to be moved out of the way in order to periodically access the equipment. The fix helped reduce the noise levels emanating from the mechanical room.